Minotaur-R overview

The solution

The robotic system is a package of off-the-shelf components and broader technology enablers redefined for the specific application area and exhibits high detection, picking and deposition performance indicators. Minotaur-R system’s basis is a 6-axis industrial robot – the sorting process and enablers are independent of robot type or make. Minotaur-R can also use any type of scara, X-Y-Z-Theta robots and employs the following enabling technologies:

-

Proprietary vision system to detect fully or partially visible springs based on their shape -not colour- using an RGB depth camera,

Figure 1: Image of the vision system

-

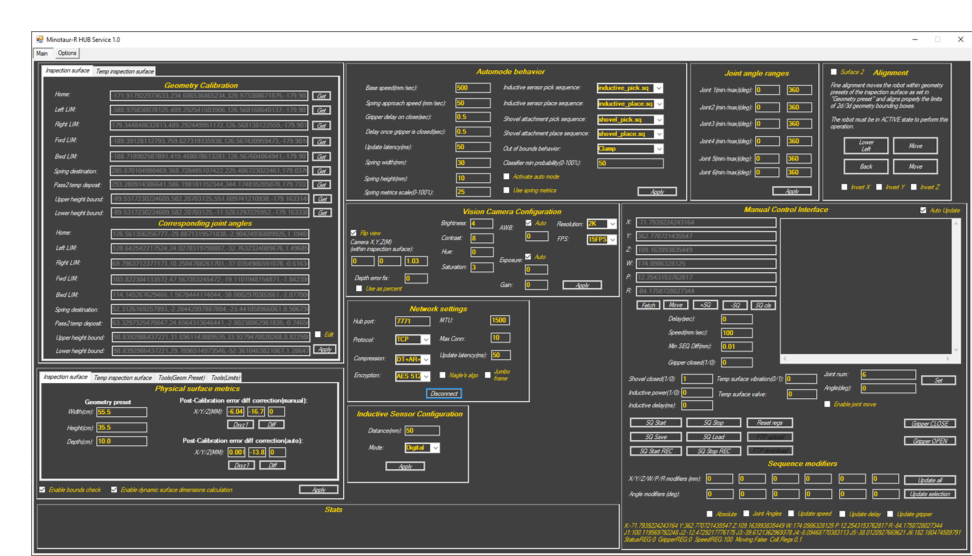

Adaptive path planning custom, PC-based software (Generates robot coordinates based on vision detection, Vision frame to robot frame calibration tool, Vision boundaries determination tool, Robot workspace determination tool, Robot movement and process sequencing, Handling of peripherals),

Figure 2: Graphical User Interface

-

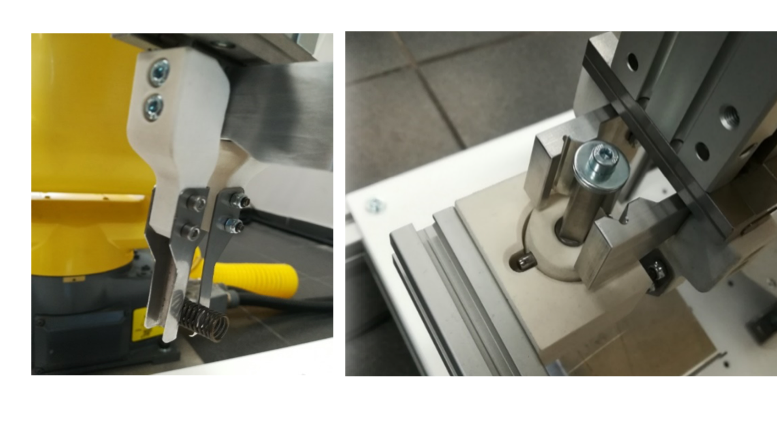

Spring Gripping system to pick non or partially occluded spring through the grasping fingers and for handling of the tools through the interfacing fingers,

Figure 3: Gripper fingers (left), tool interfacing fingers (right)

-

Metal detector simulating the radioactivity sensor to detect fully hidden springs,

-

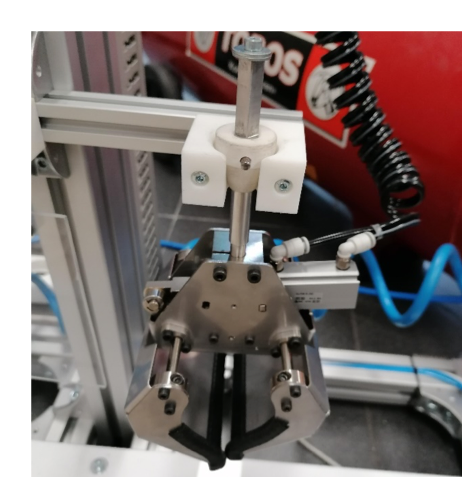

Debris Grasping system to pick hidden springs along with debris comprising of a vibration motor to reshuffle the debris and reveal possible occluded springs,

Figure 4: Debris grasping system in its tool holder

-

Secondary tray with internal edge wedges to prevent springs accumulation in the boundaries, equipped with a pneumatic actuated tipping mechanism to deposit the debris back inside the main tray. Used to place debris deposited by the debris grasping tool so as to identify hidden springs.

-

Collision detection system to compensate for uneven distribution of swarf inside the tray by providing highly accurate linear motion, Z (depth) axis compliance, end-of travel detection, soft bump stops in both the upper and lower limits.

Key Performance Indicators

| Features | Minotaur-R Metrics |

| Gripper – Grasping accuracy | 95.95% |

| Vision system – Detection accuracy | 98.57% |

| Inductive sensing/Radioactivity sensing – Detection accuracy | 100% |

| Operational time – Maintenance frequency requirements | Less than 1hr every 3 days |

| Speed of operation – Total springs removed per day | >350 springs/day (3-4min average cycle time) |

| Reliability – Human intervention requirements for system restoring | Less than 1hr every 5 days |